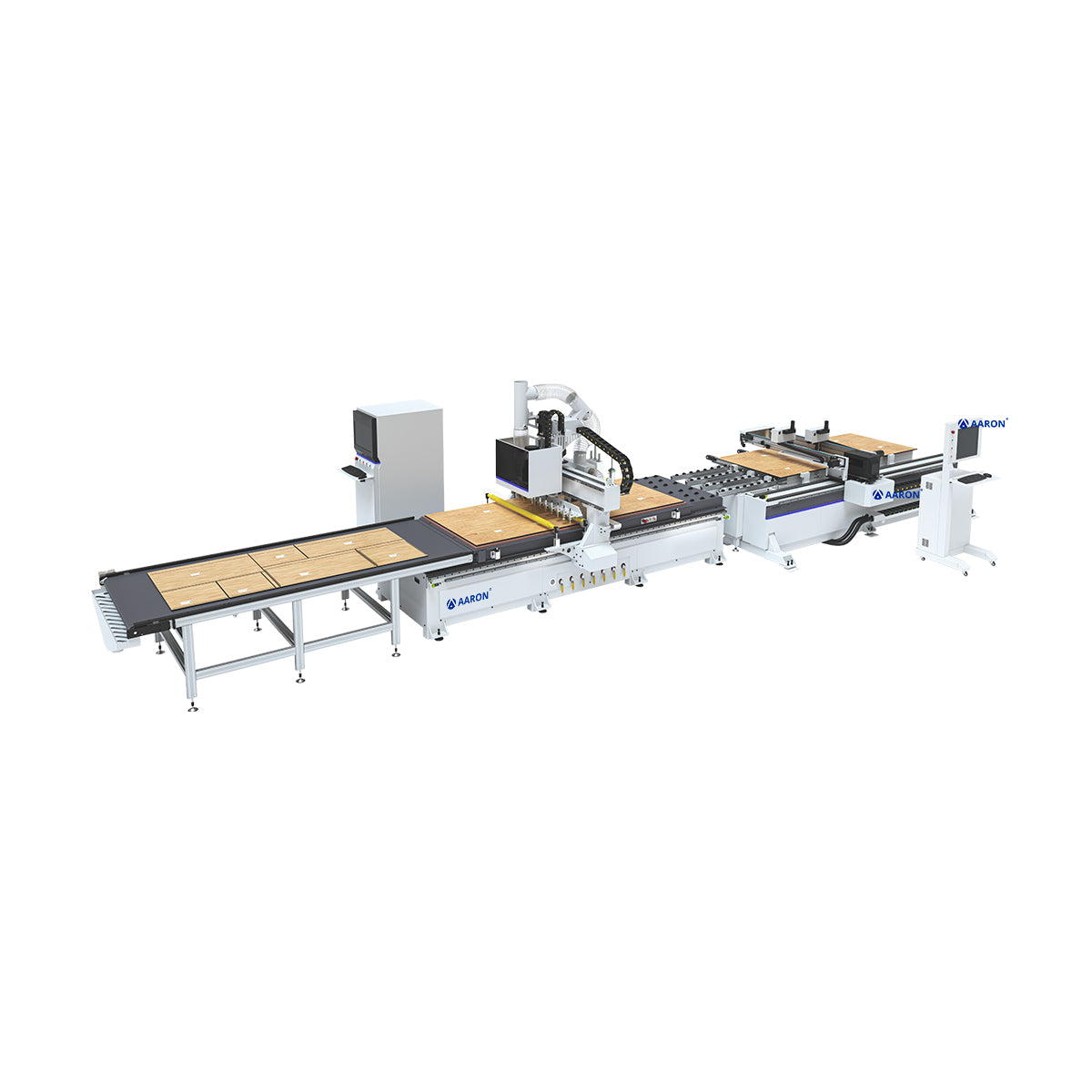

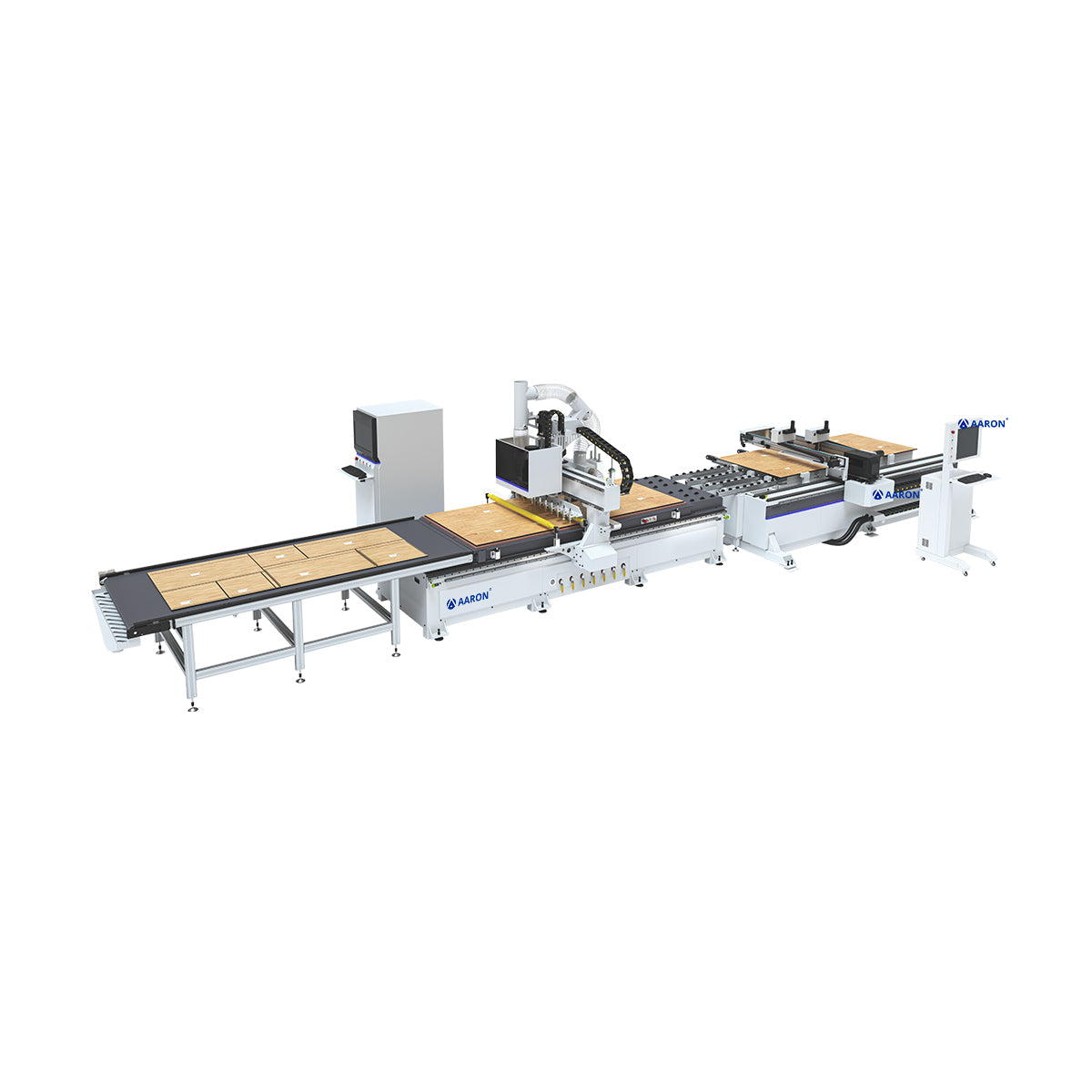

Aaron PURE Max - Advanced High-Speed PUR Edgebander (V-Belt Feeding)

Aaron PURE Max - Advanced High-Speed PUR Edgebander (V-Belt Feeding)

Aaron PURE Max Features

- Future-proof and durable PUR adhesion

- Up to 24 m/min feed speed

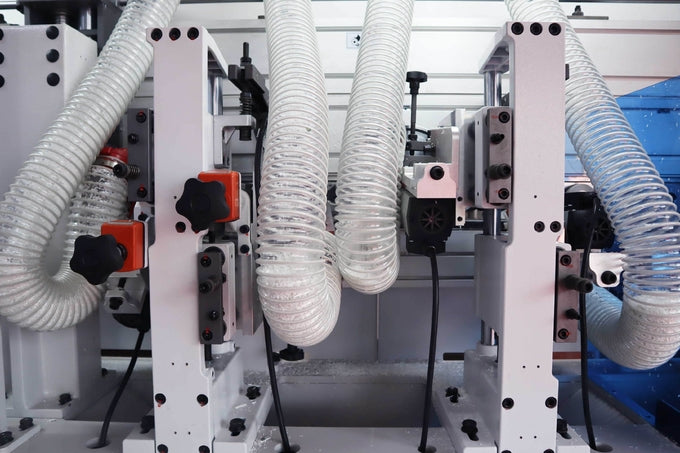

- Heavy steel composition of the pressure bean ensures stability during high-volume operation

- Heavy lifting: use thickened screw rod + smooth rod, more accurate transmission up and down, more uniform pressure on the board, more stable processing

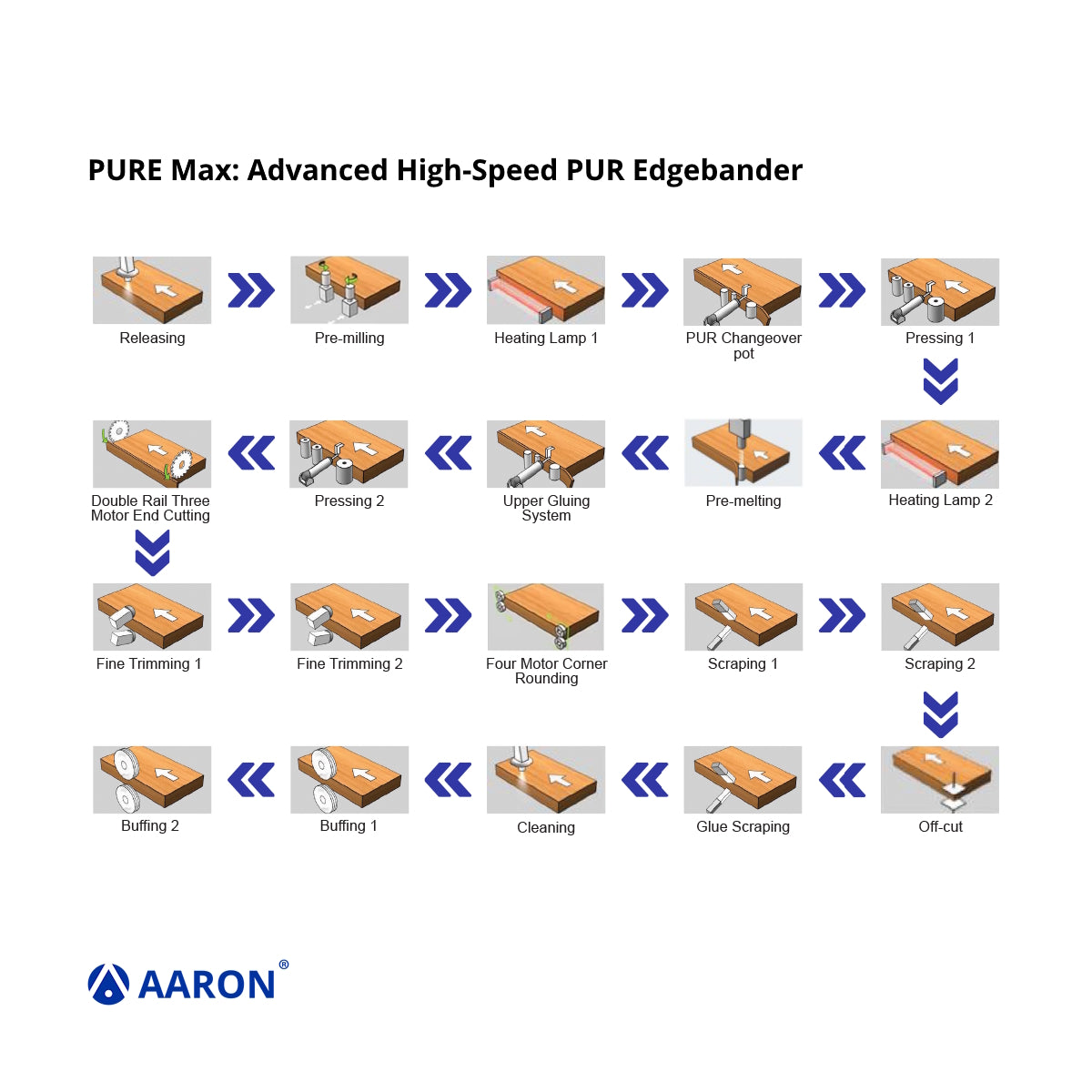

Process

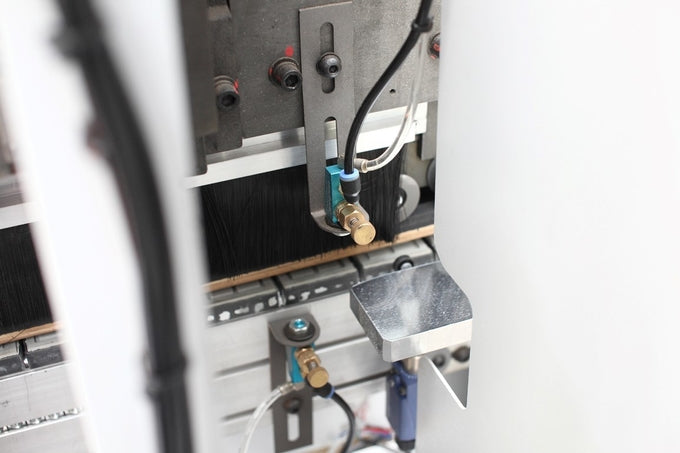

- Separation/release spray

- Pre-milling

- Heating lamp 1

- PUR changeover pot

- Pressing 1

- Heating lamp 2

- Pre-melting

- Upper gluing system

- Pressing 2

- Double rail three motor end cutting

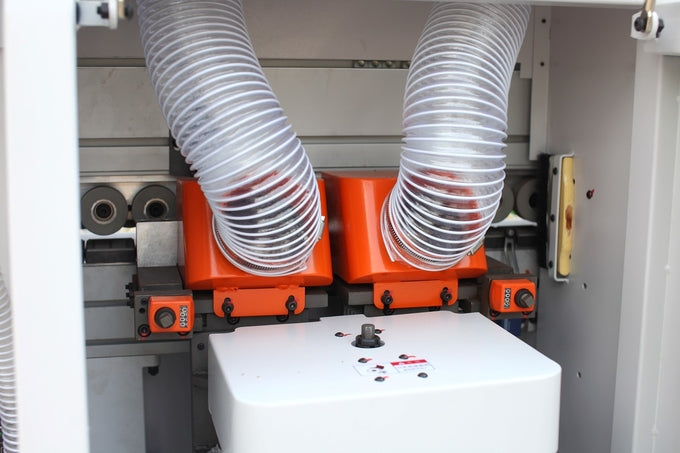

- Fine trimming 1

- Fine trimming 2

- Four motor corner rounding

- Scraping 1

- Scraping 2

- Off cut

- Glue scraping

- Cleaning

- Buffing 1

- Buffing 2

Specifications

Beam lifting: CNC lifting

Total power: 33 kW

Overall size: 10500 x 1000 x 1800 mm

Feed speed: 14 - 20 - 24 m/min

Tape thickness: 0.4 - 3 mm

Panel thickness: 10 - 60 mm

Panel length: ≥ 120 mm

Panel width: ≥ 40 mm

Working air pressure: 0.6 mpa

Min. panel size: 40 x 300 mm (corner rounding on)

EVA vs PUR Edgebanders

When choosing between EVA (ethylene-vinyl acetate) and PUR (polyurethane reactive) edgebanding machines, the decision hinges on adhesive performance, durability, and long-term value. Here are some advantages of PUR Edgebanders.

Adhesive Performance & End-Result Quality

EVA: Uses thermoplastic glue that melts and re-solidifies with temperature changes. While cost-effective, it produces thicker glue lines, which can be visible on dark-coloured panels and may lead to aesthetic imperfections like glue overflow or yellowing over time.

PUR: Reacts with moisture in the air to form a permanent, cross-linked bond. This creates near-invisible glue lines, seamless edges, and superior aesthetics—critical for high-end cabinetry. PUR’s thinner application also reduces waste

Durability & Environmental Resistance

EVA: Vulnerable to heat, moisture, and aging. In kitchens, bathrooms, or other humid environments, EVA-bonded edges risk delamination or cracking over time.

PUR: Offers exceptional resistance to heat (up to 180°C vs. EVA’s 75–95°C), moisture, and chemicals. It remains flexible in cold temperatures (-30°C vs. EVA’s 0°C threshold), making it ideal for Australia's diverse and demanding environments

Environmental & Operational Benefits

EVA: May contain formaldehyde and emits VOCs, requiring ventilation. It also demands frequent glue pot cleaning and higher glue consumption.

PUR: Low to no VOCs and formaldehyde (compliant with E0 standards), reducing workplace hazards. Though PUR requires nightly system purging, its lower glue usage (up to 20% less) potentially offsets long-term costs

Cost vs. Long-Term Value

Upfront Cost: EVA machines are cheaper, but PUR’s durability reduces, rework, and material waste.

ROI: PUR’s extended edge lifespan means higher confidence in workmanship warranty, enhancing brand reputation.

Product features

Product features

Categories

-

CNC Nesting Machines

Upgrade your production with high-performance woodworking CNC nesting router machines engineered for...

-

Edgebanding Machines

Arborwood Machinery provides affordable edgebanders for woodworking factories of all capabilities and...

-

Panel Saws

Affordable woodworking saws and accessories Arborwood Machinery provides affordable panel saws for...

-

Woodworking Accessories and Tooling

Wide range of saw blades, router bits and glue Arborwood Machinery stocks a...